Corrugated Iron Bendigo: Unlocking the Potential of a Sustainable Building Revolution

Introduction

Welcome to an in-depth exploration of Corrugated Iron Bendigo, a groundbreaking concept that is reshaping the urban landscape. This article aims to unravel the intricate world of this innovative building material and its profound impact on architecture, sustainability, and economic growth. By delving into its history, global reach, and future prospects, we will uncover why Corrugated Iron Bendigo is more than just a metal; it’s a catalyst for change, offering sustainable solutions in an ever-evolving world.

Understanding Corrugated Iron Bendigo: A Definition and Its Components

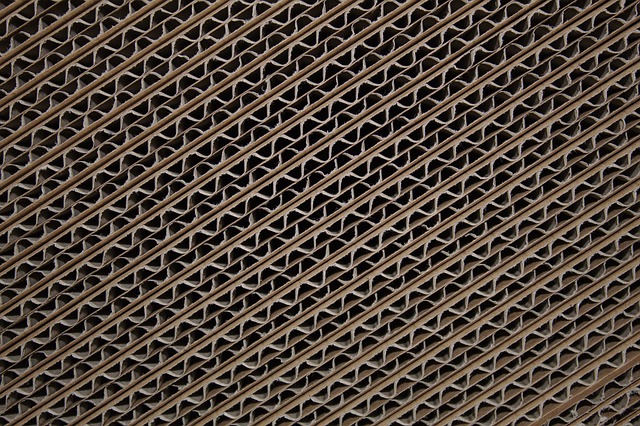

Corrugated Iron Bendigo (CIB) refers to a specific type of structural building material made from corrugated iron sheets, a versatile and durable alloy primarily composed of iron and carbon. This material has been a staple in construction for centuries, but its recent rebirth in the form of CIB is transforming the industry with its unique properties and environmental benefits.

Core Components:

- Corrugated Sheets: The centerpiece of CIB, these sheets are crafted from iron alloy, designed to withstand extreme weather conditions and provide exceptional structural integrity. The corrugated pattern adds strength while reducing material usage.

- Joists and Trusses: These components form the backbone of CIB structures, supporting walls, roofs, and floors. They can be customized for various span requirements, making them adaptable for different building designs.

- Fastening Systems: Securement is crucial in construction. CIB employs specialized fasteners, including screws, bolts, and clips, to ensure sheets are firmly attached, maintaining structural integrity over time.

Historical Context: From Industrial Revolution to Modern Renaissance

The use of corrugated iron dates back to the mid-19th century when the Industrial Revolution sparked a need for efficient, affordable building solutions. British engineers pioneered corrugated iron roofing, recognizing its potential in rapid construction and durability. This material gained popularity worldwide during the late 1800s and early 1900s, particularly for industrial buildings, bridges, and even residential structures in rural areas.

However, as architectural aesthetics evolved, corrugated metal fell out of favor in mainstream construction. It was largely replaced by more aesthetically pleasing materials like brick and wood. Yet, beneath the surface, the potential of corrugated iron remained dormant, waiting for a resurgence that would address contemporary challenges.

Global Impact and Trends: A Revitalized Material on the World Stage

In recent years, Corrugated Iron Bendigo has experienced a remarkable global revival, driven by a growing awareness of sustainability, cost-effectiveness, and efficient construction practices. Here’s how CIB is making waves worldwide:

| Region |

Trends and Impact |

| Europe |

The European Union’s push for energy efficiency and sustainable building practices has fueled the adoption of CIB. Countries like Germany and the UK are leading the way, incorporating CIB into modern architectural designs, particularly in green buildings and retrofits. |

| North America |

With a growing demand for cost-effective, quick-to-build structures, North America is embracing CIB. The material’s resilience to extreme weather makes it an ideal choice for regions prone to natural disasters. Additionally, its use in prefabricated construction is gaining traction. |

| Asia-Pacific |

This region, particularly Australia and New Zealand, has a rich history with corrugated metal but is now experiencing a surge in CIB innovation. Local architects are exploring the material’s potential in sustainable, high-performance buildings, blending traditional aesthetics with modern design. |

| Emerging Markets |

Countries in Africa and South America are turning to CIB for its affordability and ease of construction. It offers a viable solution for rapid urban development while ensuring structural integrity and safety. |

Economic Considerations: Market Dynamics and Investment Scenarios

The economic landscape of Corrugated Iron Bendigo is dynamic, shaped by various factors:

- Cost-Effectiveness: CIB offers significant cost savings compared to traditional building materials. Lower material and construction costs make it an attractive option for developers and investors, especially in budget-constrained projects.

- Market Growth: Global demand for sustainable and affordable housing is driving the CIB market. According to a recent report by Market Research Future (MRFR), the global corrugated metal roofing market, a subset of CIB, is projected to reach USD 13.2 billion by 2027, growing at a CAGR of 4.5% during the forecast period.

- Investment Opportunities: The rising popularity of CIB presents investment prospects for manufacturers and developers. Innovative production techniques and unique design applications can lead to premium pricing and market differentiation.

- Government Incentives: Many governments are promoting the use of sustainable building materials, offering tax incentives and subsidies for projects incorporating CIB. These initiatives accelerate the adoption of this eco-friendly material.

Technological Advancements: Revolutionizing the Corrugated Iron Landscape

Technology plays a pivotal role in enhancing the capabilities of Corrugated Iron Bendigo:

- Advanced Manufacturing: 3D printing and laser cutting technologies are transforming CIB production. These innovations enable the creation of complex geometric patterns, improving structural efficiency while reducing material waste.

- Smart Materials: Researchers are exploring the integration of smart materials into CIB, such as temperature-sensitive alloys and self-cleaning coatings. These advancements can further enhance energy efficiency and maintenance requirements.

- Digital Design: Computer-aided design (CAD) software allows architects to create intricate CIB structures with precision. This technology streamlines the design process, enabling more complex and aesthetically pleasing buildings.

- Modular Construction: Pre-fabricated modules constructed with CIB are gaining popularity. This approach accelerates construction times, reduces on-site waste, and improves overall project efficiency.

Policy and Regulation: Shaping the Legal Framework for CIB

Governments worldwide play a crucial role in the development and adoption of Corrugated Iron Bendigo through policies and regulations:

- Building Codes: Local building codes often dictate material specifications, including minimum strength requirements for structural elements like CIB sheets. Compliance with these standards ensures safety and structural integrity.

- Environmental Regulations: Many countries have stringent environmental policies that favor sustainable building practices. CIB’s longevity and recyclability make it compliant with these regulations, promoting eco-friendly construction.

- Incentives and Subsidies: As mentioned earlier, governments offer incentives to encourage the use of CIB in green buildings and energy-efficient structures. These policies drive innovation and adoption.

- Import/Export Controls: Some regions have trade agreements or restrictions that impact the availability and cost of CIB, especially for emerging markets looking to adopt this technology.

Challenges and Criticisms: Overcoming Obstacles for Widespread Acceptance

Despite its numerous advantages, Corrugated Iron Bendigo faces challenges and criticisms that need addressing:

- Aesthetic Perceptions: One of the primary hurdles is the material’s past association with industrial buildings and rural structures. Modern architects and designers must challenge these perceptions by showcasing CIB’s versatility and aesthetic appeal in contemporary designs.

- Material Durability Concerns: While corrugated iron is renowned for its durability, some critics question its longevity in extreme climates. However, advancements in alloy compositions and protective coatings address these concerns, ensuring CIB structures withstand harsh conditions.

- Waste Management: The production and disposal of CIB sheets can lead to environmental issues if not managed properly. Recycling programs and innovative recycling techniques are emerging to mitigate waste and promote sustainable practices.

- Labor Shortages: Skilled labor is essential for CIB installation, and shortages in certain regions may hinder project timelines. Training programs and industry collaborations can help address this challenge.

Case Studies: Real-World Success Stories of Corrugated Iron Bendigo

1. The Green Oasis: Eco-Friendly Residential Complex in Sydney, Australia

In the heart of Sydney, a residential apartment complex stands as a testament to CIB’s potential in sustainable urban development. This project utilized innovative CIB design elements, incorporating green spaces and natural lighting with structural efficiency. The result is a thriving community hub that reduces environmental impact while offering modern living.

Key Features:

- Green Roofs: The building boasts extensive green roofs, utilizing CIB panels to support diverse plant life, reducing the urban heat island effect, and providing insulation.

- Natural Ventilation: Strategically placed CIB openings facilitate cross-ventilation, minimizing the need for air conditioning.

- Solar Integration: CIB facades incorporate solar panels, harnessing renewable energy for the complex’s needs.

2. Sustainable Industrial Hub: A Case Study from Germany

A former industrial site in Germany has been transformed into a thriving eco-park using Corrugated Iron Bendigo as the primary building material. This project showcases CIB’s versatility and ability to revitalize forgotten spaces.

Transformation:

- Reclamation: The site, once contaminated, was cleaned and reclaimed using CIB structures for various purposes, including offices, workshops, and event spaces.

- Eco-Friendly Design: CIB buildings incorporate natural lighting, passive cooling systems, and rainwater harvesting, minimizing the environmental footprint.

- Community Hub: The complex has become a vibrant community space, hosting startups, artists, and eco-conscious businesses, fostering innovation and sustainability.

3. Disaster-Resilient Infrastructure: Post-Hurricane Restoration in Florida, USA

Following a devastating hurricane, a coastal town in Florida turned to Corrugated Iron Bendigo for rapid and durable reconstruction of critical infrastructure.

Restoration Efforts:

- Bridge Construction: CIB trusses were utilized to rebuild damaged bridges, ensuring quick installation and superior strength to withstand future storms.

- Temporary Shelters: Temporary housing units made from CIB provided immediate relief, offering durable and cost-effective solutions for displaced residents.

- Long-Term Resilience: The material’s resistance to corrosion and high winds contributes to the longevity of these structures, enhancing the town’s resilience against future natural disasters.

Future Prospects: Mapping the Course Ahead for Corrugated Iron Bendigo

The future of Corrugated Iron Bendigo is filled with promise, as it continues to evolve and adapt to emerging trends:

- Smart Cities: CIB will play a pivotal role in building smart cities, integrating sensors and connectivity into structural elements. This enables efficient monitoring and management of urban spaces.

- 3D Printing Advancements: As 3D printing technology improves, we can expect more complex and customized CIB structures, from intricate facades to modular buildings.

- Hybrid Materials: The fusion of CIB with composite materials will create hybrid structures offering enhanced performance, combining strength, durability, and aesthetics.

- Global Market Expansion: With continued innovation, CIB is poised for significant growth in emerging markets, driving economic development and sustainable construction practices.

- Policy Innovations: Governments will continue to shape the future of CIB through policies that encourage its use, ensuring a sustainable and resilient built environment.

Conclusion: Securing a Sustainable Future with Corrugated Iron Bendigo

In conclusion, Corrugated Iron Bendigo is more than just a building material; it’s a catalyst for positive change in architecture, sustainability, and economic growth. Its global impact, technological advancements, and successful case studies underscore its potential as a game-changer in the construction industry. As we navigate an increasingly urbanized world, CIB offers a sustainable, cost-effective, and aesthetically pleasing solution to meet our housing and infrastructure needs.

FAQ Section: Answering Common Queries about Corrugated Iron Bendigo

Q1: Is Corrugated Iron Bendigo suitable for all types of climates?

A: Absolutely! With advancements in alloy compositions and protective coatings, CIB can withstand harsh conditions, including extreme temperatures and high humidity. Proper installation ensures its longevity in various climates.

Q2: How does CIB contribute to sustainable building practices?

A: CIB’s use promotes sustainability in several ways: it reduces construction waste through reusable sheets, minimizes energy consumption with efficient structural design, and offers long-term durability, reducing the need for frequent replacements. Additionally, its recyclability makes it an eco-friendly choice.

Q3: Can CIB be aesthetically appealing beyond industrial designs?

A: Definitely! Modern architects are challenging traditional perceptions by incorporating CIB into contemporary, visually stunning buildings. From sleek facades to unique interior features, CIB’s versatility allows for innovative and attractive design solutions.

Q4: What are the potential cost savings with Corrugated Iron Bendigo?

A: CIB offers significant cost advantages over traditional building materials, especially in terms of material and construction expenses. Its quick installation times and reduced waste contribute to overall project cost savings without compromising quality or safety.

Q5: How does government support impact the adoption of CIB?

A: Governments play a crucial role through policies that encourage sustainable building practices. Incentives, subsidies, and tax breaks motivate developers and architects to choose CIB, driving its market growth and fostering innovation.

Steeline Roofing Centre Bendigo offers high-quality corrugated iron for residential and commercial use at competitive prices. Known for its durability, cost-effectiveness, and ease of installation, corrugated iron is a trusted roofing option in…….

Continue Reading

Steeline Roofing Centre Bendigo is a leading provider of high-quality, durable corrugated iron products for both residential and commercial applications in Australia. They offer an extensive range of profiles, sizes, and finishes to cater to div…….

Continue Reading

Steelee Roofing Centre Bendigo is your local expert for corrugated iron roofing solutions. They offer seamless, efficient, and timely services from installation to maintenance, using high-grade materials and advanced techniques. With a focus on…….

Continue Reading

Steeline Roofing Centre Bendigo is a leading supplier of high-quality corrugated iron sheets, catering to both construction professionals and homeowners. They offer efficient order management, advanced inventory tracking, and tailored solutions…….

Continue Reading

Corrugated Iron Bendigo, supplied and installed by Steeline Roofing Centre, is a popular choice for construction due to its durability, weather resistance, and aesthetic appeal. This versatile material is ideal for residential roofing, commercia…….

Continue Reading

Steeline Roofing Centre Bendigo, located at 6 Harrien Ct, Epsom VIC 3551, Australia, is a leading provider of corrugated iron roofing solutions. They offer same-day supply and installation services for both contractors and homeowners, ensuring q…….

Continue Reading

Steeline Roofing Centre Bendigo is the go-to expert for corrugated iron roofing solutions, offering durable, aesthetically pleasing, and cost-effective options for both residential and commercial clients. With a proven track record in Bendigo, t…….

Continue Reading

Corrugated iron is a top roofing choice in Bendigo for its strength, durability, and cost-effectiveness. Steeline Roofing Centre in Epsom offers high-quality corrugated iron options for residential and commercial projects. Their expert installer…….

Continue Reading

Corrugated iron sheets are a trusted and adaptable building solution in Bendigo, offering durability, versatility, and cost-efficiency for roofs, garages, sheds, and artistic spaces. Steeline Roofing Centre Bendigo at 6 Harrien Ct, Epsom VIC 355…….

Continue Reading

Steeline Roofing Centre Bendigo offers high-quality, cost-effective corrugated iron roofing solutions for residential and commercial properties in the region. With a focus on affordability, transparency, and expert installation, they provide com…….

Continue Reading

Steeline Roofing Centre Bendigo is a trusted supplier of high-quality corrugated iron, renowned for its durability and cost-effectiveness. Suitable for both residential and commercial settings in Australia's varying climates, this versatile…….

Continue Reading

Corrugated Iron Bendigo experts, Steeline Roofing, offer custom-length, durable solutions for new builds and repairs. Located at 6 Harrien Ct, Epsom VIC 3551, Australia, they provide accessible services and products renowned for their strength a…….

Continue Reading

Corrugated Iron Bendigo is a top choice for durable, cost-effective roofing with exceptional drainage. Steeline Bendigo at 6 Harrien Ct, Epsom VIC 3551 offers high-quality products suitable for local climate and architectural styles. Their exper…….

Continue Reading

Corrugated iron, a reliable and affordable roofing solution in Bendigo for generations, has gained popularity since its 19th-century introduction due to its strength and adaptability. Steeline Roofing Centre Bendigo, located at 6 Harrien Ct, Eps…….

Continue Reading

Steelee Roofing Centre Bendigo is a premier destination for all corrugated iron needs, offering versatile and durable solutions for residential and commercial builds. Located at 6 Harrien Ct, Epsom VIC 3551, Australia, they provide an extensive…….

Continue Reading

Corrugated Iron Bendigo is a trusted supplier of high-quality corrugated iron products for both residential and commercial applications. Steeline Bendigo offers a comprehensive range, expert guidance, and tailored solutions, making them the prem…….

Continue Reading

Steeline Roofing Centre Bendigo is a leading supplier of high-quality, durable corrugated roofing sheets, offering expert advice and tailored solutions for residential and commercial properties. Located at 6 Harrien Ct, Epsom VIC 3551, Australia…….

Continue Reading

Steeline Line Bendigo is the leading provider of corrugated iron products and services in the region, offering tailored solutions for builders, homeowners, and businesses. Located at 6 Harrien Ct, Epsom VIC 3551, Australia, they provide top-notc…….

Continue Reading

Steeline Roofing Centre Bendigo is a trusted local provider of roofing solutions, offering comprehensive services with a focus on quality and customer satisfaction. They specialize in corrugated iron roofing, leveraging its durability and afford…….

Continue Reading